.png?width=470&name=What%20is%20Cultivation%20Space%20Programming%20(1).png)

Cultivation space programming (CSP) focuses on setting the foundation of the design process by identifying the operators desired design criteria and operational goals of the facility such as crop selection, production volumes, cultivation systems and/or compliance regulations. CSP is a critical aspect of any early Controlled Environment Agriculture (CEA) project as their success is largely weighted on the operational efficiencies, risk assessment, and strategic decision making surrounding crop selection and cultivation systems, all of which are defined and designed into the space planning layout.

Cultivation space programming (CSP) focuses on setting the foundation of the design process by identifying the operators desired design criteria and operational goals of the facility such as crop selection, production volumes, cultivation systems and/or compliance regulations. CSP is a critical aspect of any early Controlled Environment Agriculture (CEA) project as their success is largely weighted on the operational efficiencies, risk assessment, and strategic decision making surrounding crop selection and cultivation systems, all of which are defined and designed into the space planning layout.

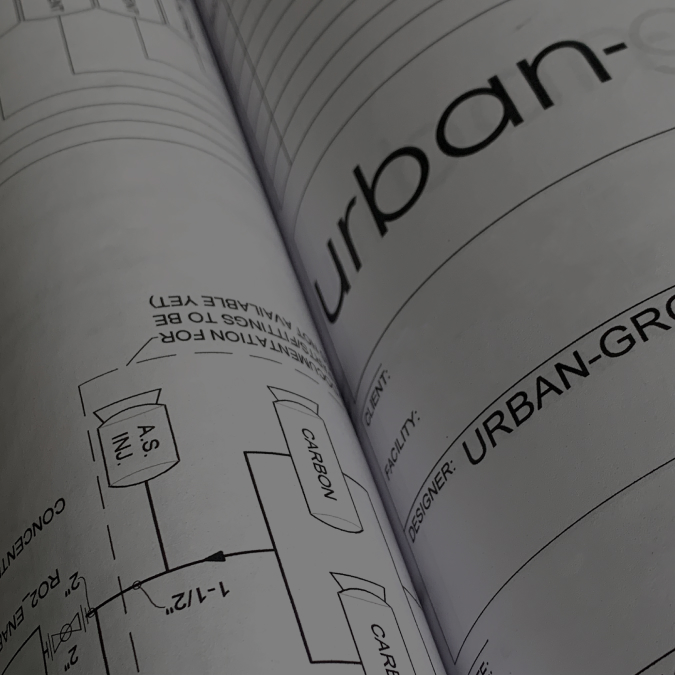

The urban-gro design team adopts a holistic approach to this initial design stage to ensure all process within the facility work together to efficiently produce an economically competitive product. By leveraging our design experience and knowledge base, special consideration is paid to how plants and people move throughout the facility to create an efficient process flow. The urban-gro team also looks at throughput calculations, including plant counts, overstock numbers, and growth stage durations to optimize space allocation and operational efficiencies.

CSP adds value early in the design process by increasing production space and identifying any deficiencies that may be present in the design philosophy or cultivation methodology early-on, before they impact facility operations. By focusing on the use of space, overall canopy square footage, and the ratio between vegetative and flower areas, the urban-gro CSP team is able to ensure maximum utilization of all space consistently throughout the facility. This depth of knowledge helps to ensure the proper sizing and specification of cultivation equipment, preventing over/under sizing while still accommodating for scale. CSP really sets the foundation for establishing and developing the metrics that are associated with cultivation, including details such as substrates type, container size, and then even down to the details around a multi-tiered racking, aisle spacing, and even corridor width.

Metrics such as plant counts, plant heights, and canopy square footage are really what drive the design process through MEP engineering (mechanical, electrical, plumbing), as well as the engineering of irrigation/fertigation systems, building control systems, air movement and sanitation systems, etc. Cultivation space planning acts as the first step to build the bedrock upon which the rest of the growing operation and supporting processes are built.