When designing a commercial grow facility, it is critical to make thoughtful decisions regarding the layout of the facility. A well-thought-out layout can help ensure your facility is running at peak performance. Here’s what you should keep in mind.

Choose an Architect with Industry Experience

The key to an effective commercial grow facility design is working with an architect with specific industry experience. For example, an architect who designs office buildings for a living might not be used to the specifications of a commercial grow facility. They need to think about utilities, space allocation, and yielding maximum efficiency for the space. An architect with relevant industry experience will be capable of anticipating these needs, offering you a design that fits the goals of a commercial grow facility.

From 2016 to 2021, the average square footage for cannabis cultivation, for example, nearly doubled from 18,000 square feet to 33,000 square feet. That means more demand, more architects, and more architectural firms with relevant commercial grow facility design experience.

Choosing a Grow Facility Layout

If every grow facility occupied a perfectly square-shaped space, it would be easier to recommend a one-size-fits-all approach. But part of what makes commercial grow facility design so important is that every area is unique. To choose the best layout for your facility, we recommend focusing on three critical factors:

Understanding Utility Specifications

A commercial grow facility design has utility requirements:

- Square footage. Did you ever order a frame from the Internet, only to be disappointed when it showed up half the size you were expecting? Square footage can be a little like that. We often think about square footage in familiar terms, such as for residential houses. But appropriate square footage for commercial grow facility design can be much more challenging. Consider visiting a facility and inquiring about the square footage or browsing commercial grow facility design templates before thinking about your own.

- Safety. Any grow facility owner must first consider the safety and security of what their growing. That means assessing the risk of your particular area (such as which natural disasters are most prevalent) and factoring that into the layout. For example, facilities in areas with high risks of earthquakes often build structures that can handle lateral movement to minimize friction and damage. Select a layout designed to withstand your region’s particular risks.

- Building materials. The materials you choose will have a considerable impact on your design plans. For example, cold-formed steel is lightweight and fireproof, giving you more flexible design choices. When considering layouts, always inquire about the building materials necessary to make the space work as designed. Choose a material like cold-formed steel that easily lends itself to modifying the layout in the future.

Purposeful Space Allocation

- Storage. Do you have a limited space that requires more vertical storage? Do your storage needs threaten the flexibility of professionals who operate the facility? Before you begin, find out your long-term storage needs. Then cross-reference those needs with the available space to see if it’s realistic to build the size of the facility you want to develop.

- Retail concerns. Some commercial grow facilities attach to retail buildings. If this is the case, you have more significant logistics to consider. Transport and movement between the two, for example, should be free-flowing. You’ll also need separate temperature controls to think about and secure sealing to ensure one space maintains integrity against the other.

Layout Best Practices

No matter what you’re building, some layout best practices should be kept in mind.

Security and access will always be necessary. You need to know every access point—as well as the potential vulnerabilities of your space. One best practice is to ensure that the growing area is sealed off, meaning there won’t be any direct access from the outside into the growing area.

Remember concerns like light management, which is especially important for building greenhouse conditions, and ensuring airflow and ventilation are adequate for your building.

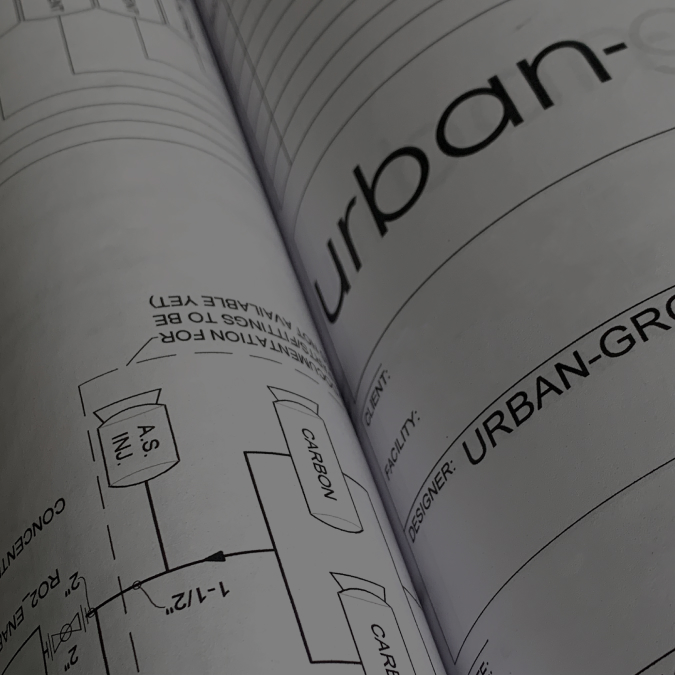

urban-gro’s Approach to Commercial Facility Design

At urban-gro, we offer value-added architectural, engineering, and construction management solutions to the Controlled Environment Agriculture (CEA) and Commercial sectors. Our approach to facility design is using the best materials and planning to ensure you develop a commercial grow facility that can meet all your needs.