From planning and design to construction and execution- opening your cultivation facility is no easy task. As experts in the industry, we know what mistakes prevent new growers from being successful. Let’s look at the top five mistakes we see and how you can avoid them.

Mistake #1 - Choosing the Wrong Location

Consider where your facility is in proximity to other businesses or residential areas. A poorly-placed location may run afoul of state regulations or local zoning issues. For example, it may be too close to a school, park, or correctional facility.

An ideal location today may not be one tomorrow. Determine the rights of the local municipality and county. Further assess risk by evaluating prevailing sentiment in the community. Analyze local laws and regulations. What if a local government can opt out of regulations allowing cultivation facilities?

Consider utility access. Establishing proper electrical service to an existing building may need a costly upgrade. You don’t want to cover the expense of digging up the street to resolve an electrical issue. Commercial electric rates often vary by time of day and from urban to rural.

Prospective growers need consistent water supplies and pressures. In some jurisdictions, growers must verify valid water rights. Water conservation is essential to both helping the environment and saving you money. Precise delivery systems optimize the use of this precious resource. Reverse osmosis and condensate reclamation conserve water supplies.

Ultimately, an ideal location is compliant at every level. Designers need to meet GACP & EUGMP compliance standards. The facility blends with its surroundings. It is energy-efficient. It offers vertical growing opportunities that increase capacity and delivers the necessary utilities without needing expensive upgrades.

Mistake #2 - Not Ensuring a Healthy Crop Environment

Proper facility design paired with MEP engineering expertise can help you avoid cross-contamination and various environmental issues that lead to poor crop yields.

Multiple studies have explored the nuances of optimum growing conditions. For example, the right HVAC system delivers an accurate number of air exchanges per hour. Airflow is essential to disrupt a plant’s micro-climate. “Boundary layer resistance” impedes needed transpiration and CO2/O2 exchange.

Ideal ambient temperatures range from 75°F to 83°F. At lower temperatures, enzymes do not work as well. At temperatures above 86°F, enzymes lose their shape and functionality.

Maintain relative humidity within a range ideal for each growth stage.

- Germination and early vegetation growth: 75-95%

- Main vegetation growth: 60-75%

- Flowering: 50-60%

Lower humidity during flowering reduces threats like mold, rot, and powdery mildew.

Ultimately, reliable regulation of heat and humidity paired with extensive knowledge of your crops’ specific needs is essential.

Mistake #3 - Not Utilizing a Proven Process

Don’t "reinvent the wheel" when designing and developing a cultivation facility. Without a proven process in place, the balancing of competing interests may run amok.

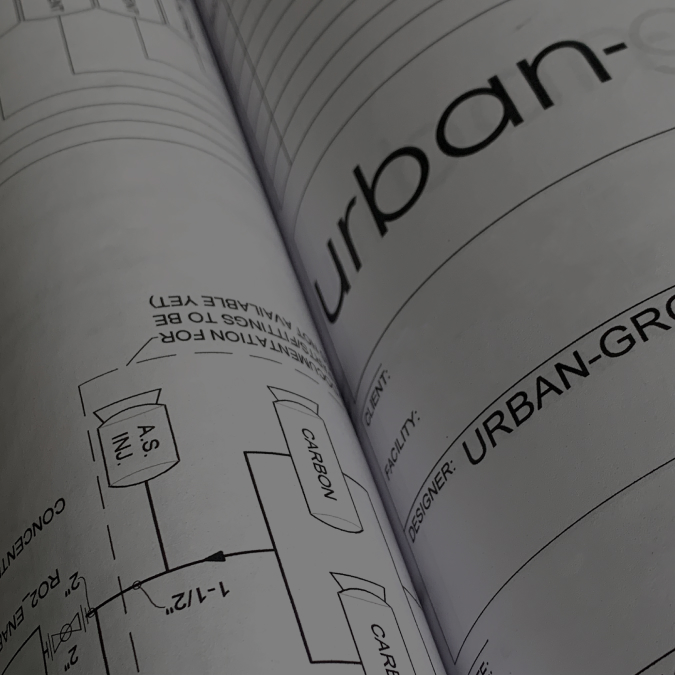

An ideal approach is urban-gro’s Integrated Architectural & Engineering Design Process. The entire team works together throughout the process, creating a vision, defining the mission, identifying needs, and establishing goals.

Mistake #4 - Hand Watering

Cultivators that choose hand watering often set themselves up for failure. Hand watering leaves each plant at the mercy of a worker, and water waste is common. Once under or over-watering occurs, it takes effort to nurse plants back to optimum health. You’ll want to choose a modern water delivery system instead.

Over time, automated systems consistently outperform hand watering. Keep in mind that automated means more than rudimentary drip systems lacking emitters. Instead, it refers to a properly engineered, pressure-compensating irrigation system that uses variable frequency drive pumps to manage different-sized grow zones.

Mistake #5 - Working Without Growing Experts

Work with experts aware of the latest developments in the design and construction of cultivation facilities. Experts know the changing circumstances and regulations from one jurisdiction to another. This knowledge and guidance will save you time and money and better prepare your growing business for success.

End-to-End Cultivation Facility Services with urban-gro

Urban-gro provides complete architectural planning and design services for cultivation facilities so that you can retrofit an existing property or design from the ground up.

Urban-gro works alongside stakeholders to design and build an efficient, compliant facility, taking care of everything from licensing applications to yield models.

Count on urban-gro for a comprehensive, turnkey approach to cultivation facility planning, programming, and design. Contact us today for prompt, professional assistance.