"Considering the topic of this article, you'd be forgiven for wondering whether it's 4/20 yet. It's not, but the booming cannabis industry is a 24/7/365 business, and there are plenty of cannabis-related topics to cover and real-world issues to settle. There is still some stigma around cannabis, and legislation reflects this. But at the same time, innovative trends continue to shape what the future of the cannabis industry will look like.

Reducing a building's carbon footprint requires a purpose-driven, whole building approach to the design and integration of plant systems and operations.

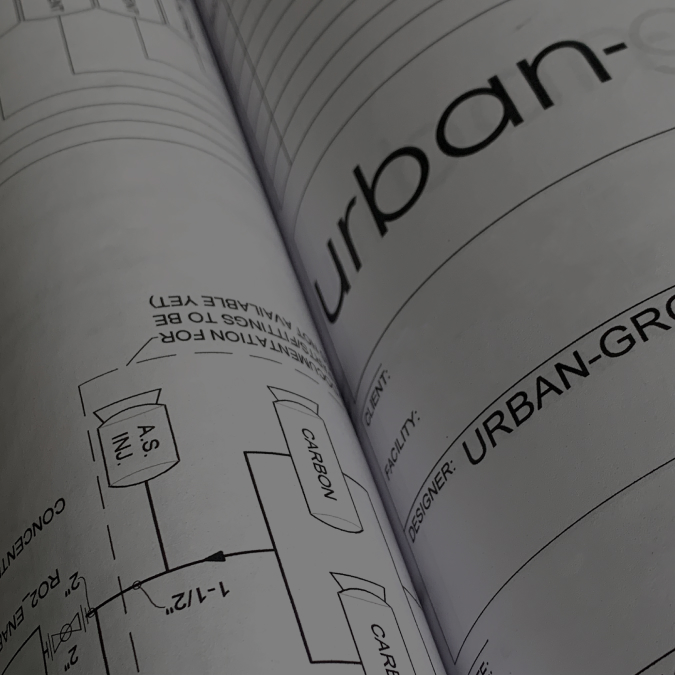

Building sustainability and resiliency is achieved through an interdisciplinary, collaborative approach committed to an integrated design process. At the heart of a facility's design and start-up process, urban-gro has a unique building + plant view to ensure the highest efficiency of integrated systems.

As we continue to advocate for federal cannabis regulatory reform, urban-gro is committed to researching, qualifying, adopting and integrating new solutions and technologies to reduce the environmental impact of Controlled Environment Agriculture (CEA).

Through urban-gro’s plant-focused approach to full building design, engineering, and complex systems integration, we recognize that improved energy and resource efficiency is not achieved through one design approach or one piece of technology.

urban-gro focuses on the following areas of building design and systems integration to improve efficiency and reduce the carbon footprint of any sized building dedicated to plant production.

- Canopy Space: Cultivation space planning optimizes the ratio of canopy to floor space by up to 20%.

- Water Consumption: By incorporating water treatment and recycling technologies, indoor cultivation can reduce water consumption by over 95% compared to traditional field crop production.

- Wastewater Treatment: High-tech indoor cultivation can reduce water consumption by an additional 80% over low-tech greenhouse operations and completely eliminate toxic discharge of fertilizer and chemical laden water.

- Lighting: According to SWEEP, indoor cultivation operations utilize ten times more energy per square foot than a typical office building. Urban-gro has a strong relationship with Fluence Bioengineering to provide industry leading LED lighting solutions. As reported in a recent Sacramento Municipal Utility District study on LED technology, Fluence’s lighting solutions not only increased THC levels and yields, but reduced lighting energy consumption by 37% and reduced overall energy savings by 25%.

- Pesticides and Chemicals: Through exclusive relationships with companies such as Arborjet, urban-gro provides commercially approved products utilizing organic ingredients. Organic ingredients, combined with biocontrols (good bugs that eat bad bugs) are at the heart of our approach to Integrated Pest Management (IPM). When we start design on new projects, our IPM team is engaged in the design process which can dramatically reduce pest pressure for the life of the building.

- Harvests: For every customer, we design facilities to produce more crops with less resources. While traditional farming operations produce one or two harvests per year, our design of indoor CEA facilities leads to an increase of four to 20 full harvests per year depending on crop type and production methodology.

On this Earth Day—and with the experience gleaned from over 300 cultivation facilities across North America—urban-gro is committed to unlocking and advancing the promise of Controlled Environment Agriculture to provide the world plant-based medicines and food crops while also reducing our carbon footprint and impact on the environment.