Investments in ag-tech are helping to make significant improvements in cannabis facility yield, quality, and consistency.

As cannabis cultivation transitions into large-scale commercial facilities, growing practices are evolving. Today’s facilities are becoming truly state-of-the-art. As the demand for cannabis increases, so does the supply, and therefore the need to produce your crop efficiently. There are also many variables within each locality to remaining compliant and sustainable. This is where technology solutions are playing a huge role.

Big agriculture already has many best practices that are now being adopted by the cannabis industry. Ag-tech can refer to both mechanical as well as digital technologies. Here we will look at fertigation, lighting, environmental automation, benching, and big data.

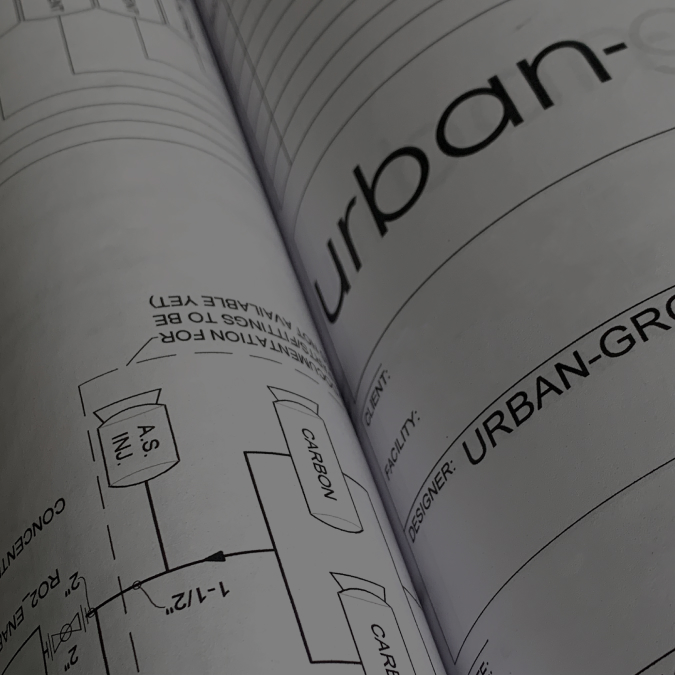

Irrigation / Fertigation

Gone are the days of hand watering. Following in lock-step with big agriculture, expect to see well-designed, built, and maintained fertigation. When all the plants receive a consistent amount of water and nutrients to the plant zone they will grow uniformly. These pressurized and automated lines make sure no one plant is receiving too much or too little water or nutrient mixes. The systems can generate notifications if there is an error on the line. These systems can also be built to include water treatment such as reverse osmosis. Professionally designed systems also take into account wastewater and how it needs to be treated before being returned into the local municipality’s water system. These systems can be hooked into the software brains of environmental automation.

Lighting

Lighting is a big part of indoor cannabis cultivation. Whether it is in a warehouse or a greenhouse with blackout shades to control the light. HPS and CMH are long-time industry standards, however, even the lights and the associated design plans to maximize light levels with fewer fixtures are improving. Additionally LED is taking hold in the industry, with many more facilities moving to checker-board their facility with HPS and LED. The lights also tie to control boards that automate the on and off times for the light. Some lights, such as the Soleil® lighting line, also come with dimming capabilities to replicate sunrise and sunset. The right reflectors, especially the ones that need minimal maintenance help to maximize light output. Re-lamping lights also guarantees light levels to ensure sustained yields.